Products

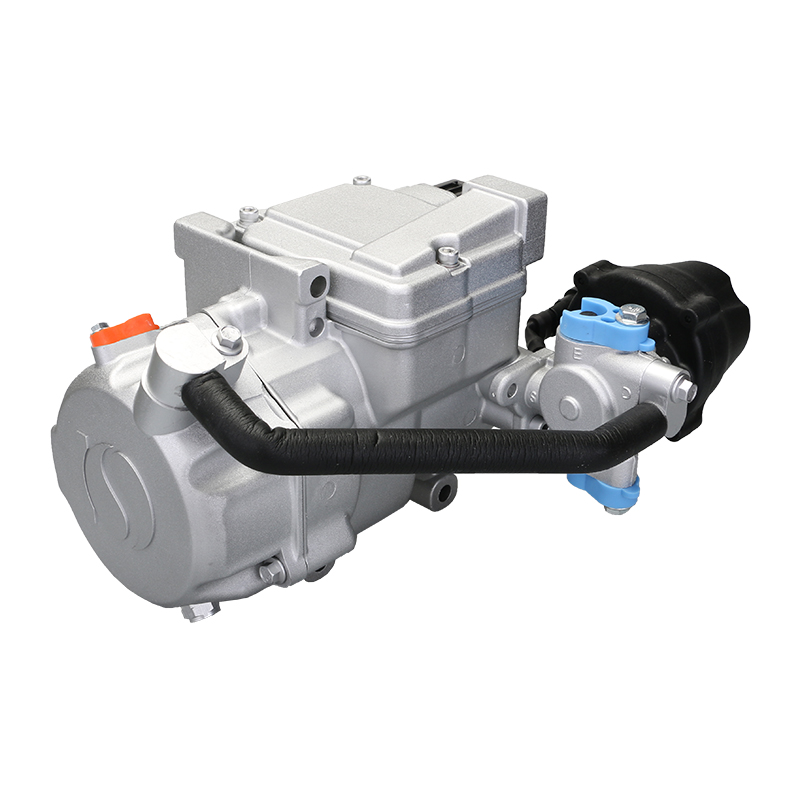

enhanced vapor injection compressor

enhanced vapor injection compressor,

enhanced vapor injection compressor,

Specifications

| Model | Enhanced Vapor Injection Compressor |

| Comperssor Type | Enthalpy-enhancing Compressor |

| Voltage | DC 12V/24V/48V/72V/80V/96V/144V/312V/540V |

| Displacement | 18ml/r / 28ml/r / 34ml/r |

| Oil | EMKARATE RL 68H/ EMKARATE RL 32H |

Scope Of Application

The compressor adopts the two-stage throttling intermediate air-jet technology, the flash evaporator for separating the gas and liquid to achieve the enthalpy increasing the compressor’s effect.

It is cooled by the side jet to mix the refrigerant at medium and low pressure, and to compress the mixed refrigerant at high pressure to improve the heat capacity at the low working temperature.

FAQs

Q1. Is OEM available?

A: Yes, product and packaging OEM manufacturing is welcome.

Q2. What is your terms of packing?

A: We pack the goods in brown paper cartons. We can pack the goods in your branded boxes after your authorization.

Q3. What is your terms of payment?

A: We accept T/T and L/C.

Electric Car Air Conditioner

● Automotive air conditioning system

● Vehicle thermal management system

● High-speed rail battery thermal management system

Parking Cooler

● Parking air conditioning system

● Yacht air conditioning system

● Private jet air conditioning system

Refrigerated Compartment

● Logistics truck refrigeration unit

● Mobile refrigeration unit

Explosive View

Enhanced vapor compressor injection: the future of compressor technology

Enhanced vapor injection compressors are an exciting advancement in compressor technology that increase efficiency and performance. This innovative technology is revolutionizing the way compressors operate, bringing numerous advantages to a variety of applications.

Enhanced vapor injection compressors use a unique process that involves injecting refrigerant into the compressor at multiple points, resulting in increased cooling capacity and energy efficiency. This advanced injection system allows precise control of refrigerant flow, improving heat transfer and overall system performance.

One of the main advantages of enhanced vapor injection compressors is the ability to operate at higher compression ratios while maintaining high efficiency. This means lower energy consumption and operating costs, making it an attractive option for a variety of industries including HVAC, refrigeration and process cooling.

In addition to energy-saving features, enhanced steam injection compressors offer enhanced performance and reliability. Precise control of refrigerant flow reduces the risk of compressor damage and extends the overall service life of the equipment, saving maintenance and replacement costs.

Additionally, this advanced technology helps reduce greenhouse gas emissions as it enables systems to operate more efficiently and reduce energy consumption. This makes enhanced steam injection compressors an environmentally friendly choice for companies looking to reduce their carbon footprint and comply with strict environmental regulations.

As the demand for more sustainable and energy-efficient technologies continues to grow, enhanced steam injection compressors will play a key role in meeting these needs. Its ability to improve performance, reduce energy consumption and minimize environmental impact makes it a valuable asset for organizations looking to enhance operations and stay ahead in today’s competitive marketplace.

In summary, enhanced vapor injection compressors represent a major leap forward in compressor technology. Its ability to deliver greater efficiency, enhanced performance and environmental benefits makes it a compelling choice for a variety of applications. As this innovative technology continues to gain traction, it is clear that enhanced vapor injection compressors are the future of compressor technology.