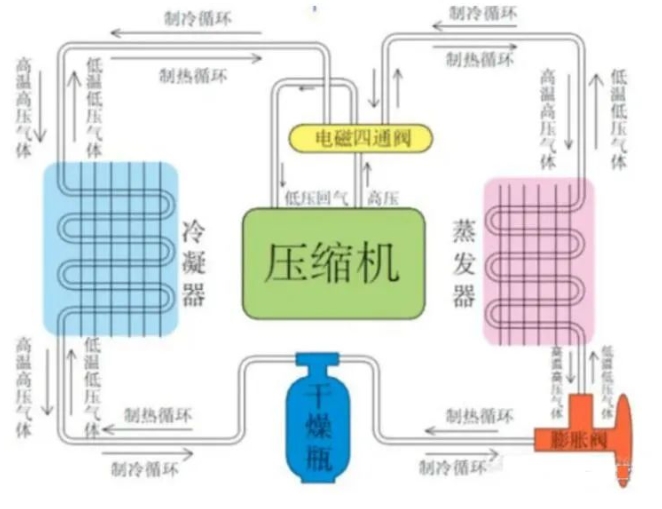

1.The control principle of the pure electric vehicle air-conditioning system is to collect information from each part of the air-conditioning equipment through the VCU (electronic control unit), form a control signal, and then transmit it to the air-conditioning controller (control circuit) bus through CAN, so that the air-conditioning controller can control the air-conditioning compression The high-voltage circuit of the machine is switched on and off to control the air conditioning system.

Troubleshooting and solutions for air-conditioning systems of pure electric vehicles

The air conditioning system cannot be started

For the problem that the air outlet does not blow out air, based on practical experience, it is mainly observed that the air conditioner switch mode is in defrost mode. If the air conditioning mode is not defrost mode, maintenance personnel need to check the speed regulating resistor and power cord, usually using a multimeter to test the voltage. If all line values are within reason, the blower needs further inspection and replacement. If the air conditioner failure is caused by wind coming from the air outlet but no cold air blowing out, you need to first check the battery capacity of the pure electric vehicle for diagnosis and repair. If the sensor temperature is normal, you need to check the pipeline and refrigerant pressure.

The cooling effect of the air conditioning system is poor

The diagnosis method of poor cooling effect is as follows: During inspection, ensure that the pure electric vehicle environment is maintained between 20-35°C, set the air outlet of the air conditioner to full blow, and the maintenance personnel set the blower to the maximum gear. Then, connect the high and low pressure of the air conditioner through the manifold pressure gauge and observe the pressure gauge reading. If the high and low pressure numbers are lower than normal, it indicates there is insufficient refrigerant in the air conditioning system. If the value is significantly lower, it indicates that there is a leak in the air conditioning duct and needs to be located. If the high pressure is normal but the low pressure is higher than 0.3MPa, and the temperature of the low pressure pipeline is very low, it may be caused by excessive vaporization of the refrigerant due to excessive adjustment of the expansion valve, so adjusting the expansion valve is enough.

The air conditioning system is noisy

For compressor vibration and noise, we must first determine whether it is caused by the failure of the rubber shock absorber or the loosening of the compressor fixing bolts. If the rubber pad is not faulty after inspection, you need to check the connections of various circuits, such as the three-phase circuit connection between the compressor and the controller. For example, when the compressor makes a harsh friction sound, it can basically be judged that the compressor itself is damaged and the compressor needs to be replaced. If the condensing fan makes loud vibration noise, first check the rubber pad where the condensing fan is installed. If the problem persists after replacement, it may be caused by wear of the condensing fan motor and the condensing fan needs to be replaced.

In addition to the above faults, the air conditioning system also has intermittent cooling problems. For this problem, it is mainly necessary to check whether the temperature of the compressor exceeds the set value of the entire vehicle system. For example, pure electric vehicles set the compressor protection temperature to 85°C. If the value exceeds this value, the system will automatically issue a compressor shutdown command. This fault is mainly caused by the failure of the compressor refrigeration function, causing the compressor temperature to be too high, and the compressor controller needs to be replaced. When replacing the controller, apply thermal silicone grease evenly on the contact surface to reduce compressor shutdown caused by overheating.

Post time: Apr-08-2024