Features of electric compressor

By controlling the motor speed to adjust the compressor output, it achieves efficient air conditioning control. When the engine is low speed, the speed of the belt driven compressor will also be reduced, which will relatively reduce the cooling effect of the air conditioner, and the use of electric compressor even when the vehicle stops running, the motor can still maintain a high speed to ensure the cooling effect of the air conditioner, so low fuel consumption and comfort are taken into account. Today, electric compressors are widely installed in HEV (hybrid) /PHEV (plug-in hybrid) vehicles.

In order to adapt to the carrying needs of different vehicles, the compressor capacity (the amount of refrigerant released by the compressor rotation one week) will also be different. Therefore, the electric compressor on the market continues to iterate with the advancement of research and development technology, and at present, the third generation of electric compressor has gradually become the mainstream product.

The composition of electric compressor

The electric compressor is composed of an inverter, a motor and a compressor

inverter

Through the high voltage battery, the direct current is converted into alternating current (three-phase), which is transmitted to the motor.

Electric machine

Through the inverter output AC (three-phase) to drive operation

compressor

The use of scroll compressor, because the compressor and the motor are directly connected, so the motor directly controls the operation of the compressor, the inverter and the motor will produce high temperature when running, so the compressor adopts the structure of cooling through the suction refrigerant.

Compressor oil for electric compressors

In order to prevent the compressor from locking, the compressor needs to be filled with compressor special oil, compressor special oil is mainly divided into two categories, namely PAG oil and POE oil.

As to the use of compressor oil , the difference between the two types of compressor oil is that PAG oil has electrical conductivity, and POE oil has insulation.

The belt-driven compressor is filled with PAG oil. Because the electric compressor needs to be installed on the HEV/PHEV/BEV vehicle, if the injected compressor oil has electrical conductivity, it will be mistaken by the system for vehicle leakage and stop the normal running of the vehicle, so the electric compressor uses POE oil with insulation.

Summary of motors for electric compressors

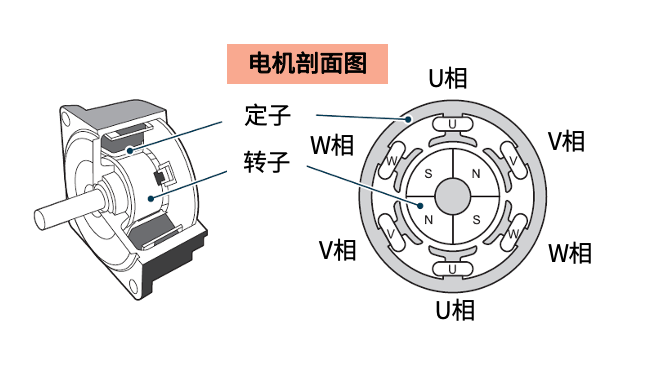

The electric compressor is used in the brushless motor, the rotor material is a permanent magnet, the stator is composed of 3 coils (U phase, V phase, W phase) winding, when there is an alternating current (3 phase) flowing through the winding, it will produce a magnetic field. By adjusting the flow path of the AC current through the drive circuit, the magnetic field can be reversed, and the magnetic field will affect the rotation of the permanent magnet rotor.

Post time: Sep-26-2023