We have designed and developed a new heat pump type air conditioning test system for new energy vehicles, integrating multiple operating parameters and conducting experimental analysis of the optimal operating conditions of the system at a fixed speed. We have studied the effect of compressor speed on various key parameters of the system during refrigeration mode.

The results show:

(1)When the system supercooling is in the range of 5-8°C, a larger refrigeration capacity and COP can be obtained, and the system performance is the best.

(2) With the increase of compressor speed, the optimal opening of the electronic expansion valve at the corresponding optimal operating condition gradually increases, but the rate of increase gradually decreases. The evaporator air outlet temperature gradually decreases and the rate of decrease gradually decreases.

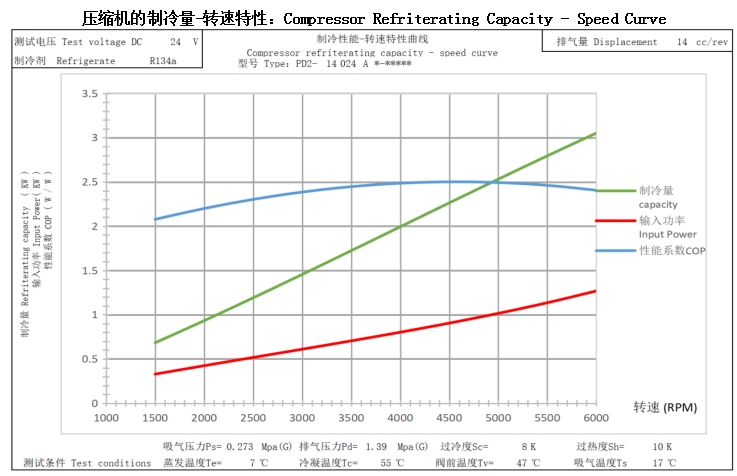

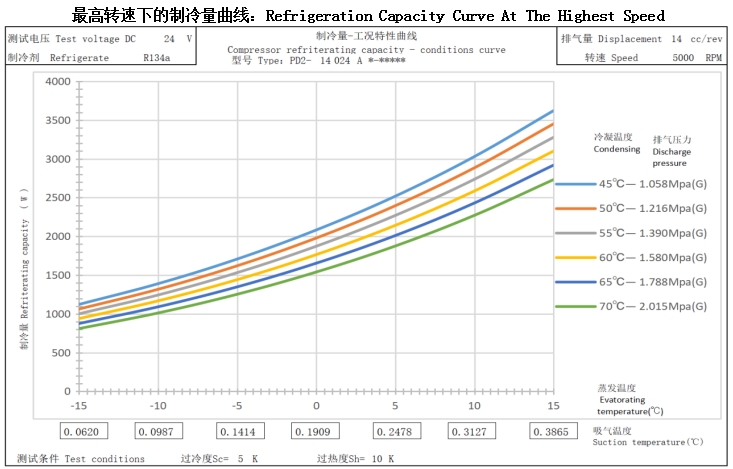

(3) With the increase of compressor speed, the condensing pressure increases, the evaporating pressure decreases, and the compressor power consumption and refrigeration capacity will increase to varying degrees, while the COP shows a decrease.

(4) Considering the evaporator air outlet temperature, refrigeration capacity, compressor power consumption, and energy efficiency, a higher speed can achieve the purpose of rapid cooling, but it is not conducive to overall energy efficiency improvement. Therefore, the compressor speed should not be excessively increased.

The development of new energy vehicles has brought about the demand for innovative air conditioning systems that are efficient and environmentally friendly. One of the focus areas of our research is examining how the speed of the compressor affects various critical parameters of the system in cooling mode.

Our results reveal several important insights into the relationship between compressor speed and air conditioning system performance in new energy vehicles. First, we observed that when the system’s subcooling is in the 5-8°C range, the cooling capacity and coefficient of performance (COP) increase significantly, allowing the system to achieve optimal performance.

Furthermore, as the compressor speed increases, we notice a gradual increase in the optimal opening of the electronic expansion valve at the corresponding optimal operating conditions. But it is worth noting that the opening increase gradually declined. At the same time, the evaporator outlet air temperature gradually decreases, and the decrease rate also shows a gradual downward trend.

Additionally, our study reveals the impact of compressor speed on pressure levels within the system. As the compressor speed increases, we observe a corresponding increase in condensation pressure, while the evaporation pressure decreases. This change in pressure dynamics was found to lead to varying degrees of increase in compressor power consumption and refrigeration capacity.

Considering the implications of these findings, it is clear that while higher compressor speeds can promote rapid cooling, they do not necessarily contribute to overall improvements in energy efficiency. Therefore, it is crucial to strike a balance between achieving the desired cooling results and optimizing energy efficiency.

In summary, our study clarifies the complex relationship between compressor speed and refrigeration performance in new energy vehicle air conditioning systems. By highlighting the need for a balanced approach that prioritizes cooling performance and energy efficiency, our findings pave the way for the development of advanced air conditioning solutions designed to meet the ever-changing needs of the automotive industry.

Post time: Apr-20-2024