Electric vehicle air conditioning compressor (hereinafter referred to as electric compressor) as an important functional component of new energy vehicles, the application prospect is broad. It can ensure the reliability of the power battery and build a good climate environment for the passenger cabin, but it also produce a complaint of vibration and noise. Because there is no engine noise masking, electric compressor noise has become one of the main noise sources of electric vehicles, and its motor noise has more high-frequency components, making the sound quality problem more prominent. The sound quality is an important index for people to evaluate and buy cars. Therefore, it is of great significance to study the noise types and sound quality characteristics of electric compressor through theoretical analysis and experimental means.

Noise types and generation mechanism

The operation noise of electric compressor mainly includes mechanical noise, pneumatic noise and electromagnetic noise. The mechanical noise mainly includes friction noise, impact noise and structure noise. The aerodynamic noise mainly includes exhaust jet noise, exhaust pulsation, suction turbulence noise and suction pulsation. The mechanism of noise generation is as follows:

(1) friction noise. Two objects contact for relative motion, friction force is used in the contact surface, stimulate the object vibration and emit noise. The relative motion between the compression maneuver and the static vortex disk causes friction noise.

(2) Impact noise. Impact noise is the noise generated by the impact of objects with objects, which is characterized by a short radiation process, but a high sound level. The noise generated by the valve plate striking the valve plate when the compressor is discharging belongs to the impact noise.

(3) Structural noise. The noise generated by excitation vibration and vibration transmission of solid components is called structural noise. The eccentric rotation of compressor rotor and rotor disk will generate periodic excitation to the shell, and the noise radiated by the vibration of the shell is structural noise.

(4) exhaust noise. Exhaust noise can be divided into exhaust jet noise and exhaust pulsation noise. The noise produced by high temperature and high pressure gas ejecting from the vent hole at high speed belongs to exhaust jet noise. The noise caused by intermittent exhaust gas pressure fluctuation belongs to exhaust gas pulsation noise.

(5) inspiratory noise. Suction noise can be divided into suction turbulence noise and suction pulsation noise. The air column resonance noise generated by unsteady airflow flowing in the intake channel belongs to the suction turbulence noise. The pressure fluctuation noise produced by the periodic suction of the compressor belongs to the suction pulsation noise.

(6) Electromagnetic noise. The interaction of magnetic field in the air gap produces radial force that changes with time and space, acts on the fixed and rotor core, causes periodic deformation of the core, and thus generates electromagnetic noise through vibration and sound. The working noise of compressor drive motor belongs to electromagnetic noise.

NVH test requirements and test points

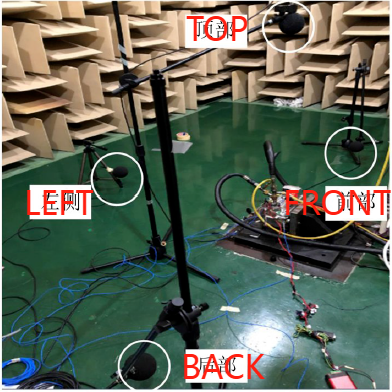

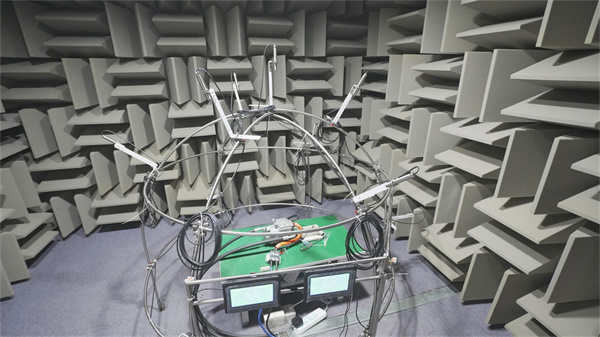

The compressor is installed on A rigid bracket, and the noise test environment is required to be a semi-anechoic chamber, and the background noise is below 20 dB(A). The microphones are arranged at the front (suction side), rear (exhaust side), top, and left side of the compressor. The distance between the four sites is 1 m from the geometric center of the compressor surface, as shown in the following figure.

Conclusion

(1) The operating noise of the electric compressor is composed of mechanical noise, pneumatic noise and electromagnetic noise, and the electromagnetic noise has the most obvious impact on the sound quality, and optimizing the electromagnetic noise control is an effective way to improve the sound quality of the electric compressor.

(2) There are obvious differences in the objective parameter values of sound quality under different field points and different speed conditions, and the sound quality in the rear direction is the best. Reducing the compressor working speed under the premise of satisfying the refrigeration performance and preferentially choosing the compressor orientation towards the passenger compartment when carrying out the vehicle layout are conducive to improving people's driving experience.

(3) The frequency band distribution of the characteristic loudness of the electric compressor and its peak value is only related to the field position, and has nothing to do with the speed. The loudness peaks of each field noise feature are mainly distributed in the middle and high frequency band, and there is no masking of engine noise, which is easy to be recognized and complained by customers. According to the characteristics of acoustic insulation materials, adopting acoustic insulation measures on its transmission path (such as using acoustic insulation cover to wrap the compressor) can effectively reduce the impact of electric compressor noise on the vehicle.

Post time: Sep-28-2023