Aiming at the wear problem of the stall mechanism of the scroll compressor of automobile air conditioner, the power characteristics and wear characteristics of the stall mechanism were studied.

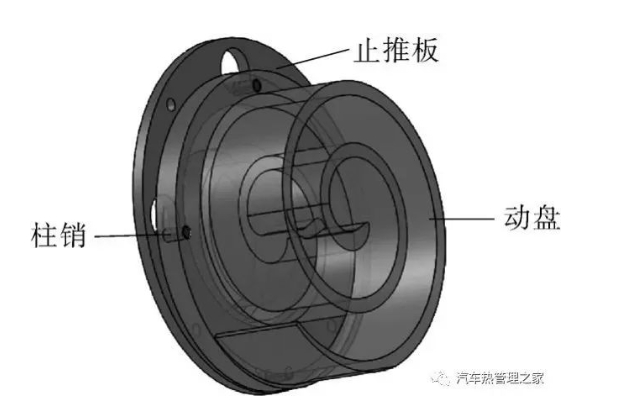

Working principle of anti-rotation mechanism/Structure of cylindrical pin anti-rotation mechanism

The pin shaft is fixed on the moving plate through interference fit, and there is a round hole on the thrust plate. The thrust plate is fixed on the frame through positioning pins, and the end surface of the thrust plate contacts the bottom plate of the moving plate to provide axial thrust. In order to reduce thrust bearing wear, a steel wear-resistant plate is installed between the thrust plate and the moving plate bottom plate.

Force analysis of anti-rotation mechanism

Although the pins make circular motion relative to the inner wall of the circular hole, strictly speaking, not every pair of pins is in close contact with the circular hole, that is, there is contact pressure.

Wear cause analysis

1. Wearing form

After dismantling and inspecting the automotive air-conditioning scroll compressor that had undergone durability testing, it was found that some areas on the inner wall of the circular hole on the thrust plate were brighter than other areas, as shown in the figure, indicating slight wear. In addition, the wear conditions of the inner walls of the four circular holes are roughly the same.

For areas with severe wear, there are small shallow scratches along the circumferential direction of the inner wall of the round hole. These scratches are mainly concentrated in two areas near the intersection of the inner wall of the round hole and its distribution circle.

The pin makes a circular motion along the inner wall of the circular hole. Due to the interference fit, there is both relative rolling and sliding between the pin and the inner wall of the round hole.

The movement of the pin along the inner wall of the round hole is mainly sliding, and the sliding speed is about 2-3 times the rolling speed. According to the definition of adhesive wear, it can be determined that the wear on the inner wall of the circular hole is a form of adhesive wear.

Improvements

Since the oil film thickness ratio reflects the lubrication condition of the friction pair surface, improving the lubrication condition between the pin and the inner wall of the circular hole can be considered from the perspective of increasing the oil film thickness ratio. Directly reducing the surface roughness of the pin shaft or the inner wall of the circular hole can also help increase the oil film thickness ratio and improve lubrication conditions.

in conclusion

(1) At any given moment, in the anti-rotation mechanism, there is only one pin as the anti-rotation element. The angle between the vector whose center points to the center of the circular hole and the vector at the center of the circular hole is along the tangent of the distribution circle where the pin is located. minimize.

(2) In the anti-rotation mechanism, the movement of the pin along the inner wall of the round hole is mainly sliding, and the sliding speed is about 2 to 3 times the rolling speed, indicating that the inner wall of the pin is worn. Round holes are a form of adhesive wear.

(3) The main reason for the wear of the inner wall of the circular hole is that the oil film thickness ratio corresponding to the contact area between the pin and the inner wall of the circular hole is too small, and the lubrication conditions are relatively poor. When the compressor suction pressure and discharge pressure are 0.3 and 2.0 MPa respectively, and the rotation speed is 6000 r/min, the film thickness ratio in the contact area is only 0.21, and it is almost impossible to form a lubricating oil film.

(4) Measures such as increasing the equivalent contact radius between the pin and the round hole, increasing the viscosity of the lubricating oil in the oil film entrance area, and reducing the load per unit line contact length between the pin and the inner wall of the round hole can effectively increase the number of pins and round holes. The film thickness ratio corresponding to the inner wall contact improves wear.

Post time: Apr-13-2024