Reading guide

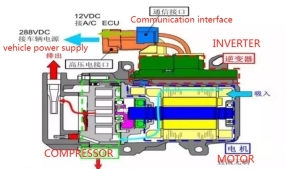

Since the rise of new energy vehicles, automotive air conditioning compressors have also undergone great changes: the front end of the drive wheel has been canceled, and a drive motor and a separate control module have been added.

However, because the DC battery is used in electric vehicles, if you want to drive the normal and stable work of the motor, you must use the control module (inverter) to convert direct current into alternating current. That is, through the voltage control device in the control module, the duty cycle pulse modulation control voltage is added in turn according to a certain rule.

When the DC high voltage current passes through the inverter, the three-phase sinusoidal AC current is formed at the output end to ensure the smooth operation of the three-phase permanent magnet synchronous motor and generate enough torque to drive the compressor.

From the appearance alone, it is difficult to associate it with the compressor. But in its heart, or we are familiar with the friend ------ scroll compressor.

Because of its low vibration, low noise, long service life, light weight, high speed, high efficiency, small size and many other advantages, it is widely used in new energy electric vehicles.

The core components of a scroll compressor consist of two intermeshing vortices:

A fixed scroll disk (fixed to the frame);

A rotating scroll disk (driven directly by an electric motor to make a small rotational motion around a fixed scroll disk). Because their lines are the same, they are combined by staggered 180°, that is, the phase Angle is 180° different.

When the drive motor rotates to drive the vortex disk, the cooling gas is sucked into the outer part of the vortex disk through the filter element. With the rotation of the drive shaft, the vortex disk runs according to the track in the fixed scroll disk.

The cooling gas is gradually compressed in the six crescent-shaped compression cavities composed of the moving and fixed scroll disks. Finally, the compressed refrigeration gas is continuously discharged from the center hole of the fixed scroll disk through the valve plate.

Because the working chamber is gradually smaller from the outside to the inside and in different compression conditions, it ensures that the scroll compressor can continuously inhale, compress and exhaust. And the scroll disk can be used for up to 9000 ~ 13000r/min revolution, the output of large displacement is enough to ensure the requirements of vehicle air conditioning refrigeration.

In addition, the scroll compressor does not need an intake valve, only an exhaust valve, which can simplify the structure of the compressor, eliminate the pressure loss of opening the air valve, and improve the compression efficiency.

Post time: Oct-05-2023