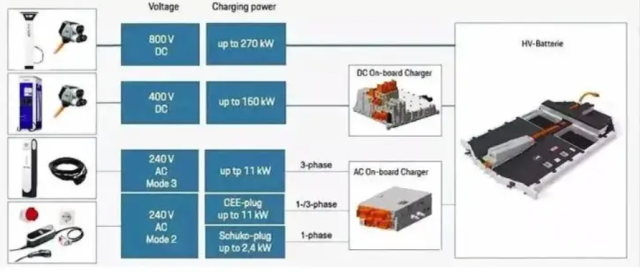

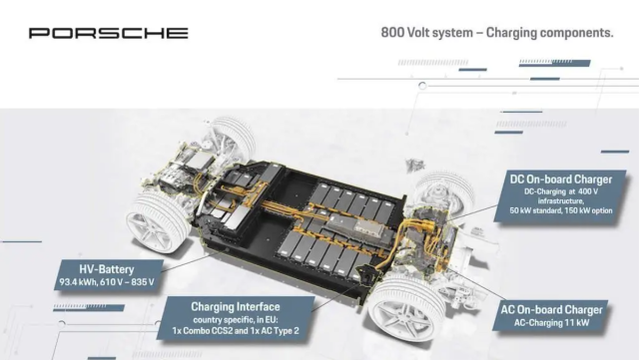

The interior of a car is made up of a lot of components, especially after electrification. The purpose of the voltage platform is to match the power needs of different parts. Some parts require a relatively low voltage, such as body electronics, entertainment equipment, controllers, etc. (generally 12V voltage platform power supply), and some require a relatively high voltage, such as battery systems, high voltage drive systems, charging systems, etc. (400V/800V), so there is a high voltage platform and low voltage platform.

Then clarify the relationship between 800V and super fast charge: Now the pure electric passenger car is generally about 400V battery system, the corresponding motor, accessories, high voltage cable is also the same voltage level, if the system voltage is increased, it means that under the same power demand, the current can be reduced by half, the entire system loss becomes smaller, the heat is reduced, but also further lightweight, the vehicle performance is of great help.

In fact, fast charging is not directly related to 800V, mainly because the charging rate of the battery is higher, allowing greater power charging, which itself has nothing to do with 800V, just like Tesla's 400V platform, but it can also achieve super fast charging in the form of high current. But 800V is to achieve high-power charging provides a good foundation, because the same to achieve 360kW charging power, 800V theory only needs 450A current, if it is 400V, it needs 900A current, 900A in the current technical conditions for passenger cars is almost impossible. Therefore, it is more reasonable to link 800V and super fast charge together, called 800V super fast charge technology platform.

At present, there are three types of high-voltage system architectures that are expected to achieve high-power fast charge, and the full high-voltage system is expected to become the mainstream:

(1) Full system high voltage, that is, 800V power battery +800V motor, electric control +800V OBC, DC/DC, PDU+800V air conditioning, PTC.

Advantages: High energy conversion rate, for example, the energy conversion rate of the electric drive system is 90%, the energy conversion rate of DC/DC is 92%, if the whole system is high voltage, it is not necessary to depressurize through DC/DC, the system energy conversion rate is 90%×92%=82.8%.

Weaknesses: The architecture not only has high requirements on the battery system, electric control, OBC, DC/DC power devices need to be replaced by Si-based IGBT SiC MOSFET, motor, compressor, PTC, etc. need to improve the voltage performance, short-term car end cost increase is higher, but in the long term, after the industrial chain is mature and the scale effect has. The volume of some parts is reduced, the energy efficiency is improved, and the cost of the vehicle will fall.

(2) Part of the high voltage, that is, 800V battery +400V motor, electric control +400V OBC, DC/DC, PDU +400V air conditioning, PTC.

Advantages: basically use the existing structure, only upgrade the power battery, the cost of car end transformation is small, and there is greater practicality in the short term.

Disadvantages: DC/DC step-down is used in many places, and the energy loss is large.

(3) All low-voltage architecture, that is, 400V battery (charging 800V in series, discharging 400V in parallel) +400V motor, electric control +400V OBC, DC/DC, PDU +400V air conditioning, PTC.

Advantages: The car end transformation is small, the battery only needs to be transformed BMS.

Disadvantages: series increase, battery cost increase, use the original power battery, the improvement of charging efficiency is limited.

Post time: Sep-18-2023